Products

.jpg) |

Product Name: Multifunction hydraulic control valve Product Introduction: With the continuous development of modern high-rise buildings and Water Department circles, as well as users increasingly high demand, the company combined with the actual situation on the basis of hydraulic control valves on the first generation, the successful production of second-generation dual-control function rooms hydraulic control valve. After which it can use, depending on the environment before using artificial-time adjustment, can automatically ensure the safe operation of the pipe network, the body uses streamline design, all castings are used to rust spray, all moving parts are made of corrosion materials, external catheter and guide all valves are all-copper or stainless steel, assembled after valve no longer paint treatment, all the media have better contact surface corrosion resistance, by changing the external pilot valve and conduit joining form which can evolve cost-bit control valves, valves, muffler / eliminate hammer / slow start / slow closing check valve, safety relief valves, electric remote control valve. Depending on the use of media and pressure, I produced piston and diaphragm for users to choose two. |

Application Standard

Quality assurance: ISO9001

Flange Standard: GB / T 17241.6API 598 GB / T 9113

Experimental Standard: GB / T 13927

Design: JB / T 10674

Performance range

| PN(Mpa) | 1.0 | 1.6 | 2.5 |

| (Mpa) | 1.5 | 2.4 | 3.8 |

| (Mpa) | 1.1 | 1.76 | 2.75 |

| (Bar) | 6 | 0.6 | 0.6 |

| Working temperature | <80℃ | ||

| For media | Water and physical and chemical properties similar to water media Germany | ||

Features and Benefits

★ has a slow start function, solve the traditional man-off valve pump.

★ with slow closing function, can be artificially adjusted set closing time, automatically slow closing, eliminate water hammer.

★ good return function. Using with good elasticity and high wear resistance of rubber sealing material, after closing up to leak.

★ sensitive, does not appear out of control.

★ without human action. Are automatic in the whole process of the pipe network running.

★ easy maintenance without removal from the pipeline entire valve, identify the cause of the malfunction in the repair, overhaul only partial.

★ The valve inside and outside and all the perishable parts are electrostatic spray, long used in the sewage will not rust.

★ vertical and horizontal installation in the pipeline can be absorbed unchanged performance.

The main valve flow graph

The main components Material

| NO . | Part Name | Selection of materials |

| 1 | bonnet | gray iron, ductile iron, carbon steel, stainless steel |

| 2 | Spring | spring steel, stainless steel |

| 3 | diaphragm plate | Ductile |

| 4 | patch | nitrile rubber |

| 5 | Stem | 2Cr13 |

| 6 | valve | Ductile |

| 7 | seal | nitrile rubber |

| 8 | Seal plate | Ductile |

| 9 | Seat | stainless steel |

| 10 | body | gray iron, ductile iron, carbon steel, stainless steel |

Typical installation diagram

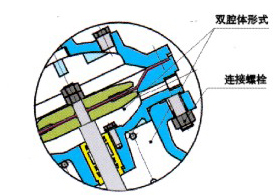

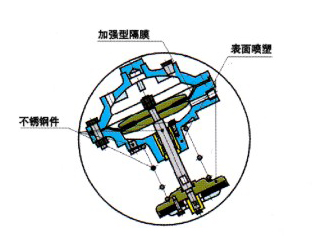

In order to more effectively prevent water hammer generation, the second generation of diaphragm type hydraulic control valve body in the form of dual chamber control room design. Depending on the application the two chambers can be isolated from each other or the same, in order to achieve slow opening, slow closing or quick closing and other auxiliary functions. In some extent hindered the generation of the hammer or the intensity level decomposition of water hammer, other equipment protection after the valve from damage. In addition, the bonnet and the upper chamber as a single entity, so that the valve cover, the upper chamber, the valve stem, the valve disc as a whole, just loosen the bolts on the body, you can be one and removed easily repair and replacement of wearing parts.

1, a small ball 2, the pilot valve 3, the small ball 4, a small ball valve 5, the needle valve 6, the small valve

The second generation of hydraulic control valve diaphragm a change of the first generation of hydraulic diaphragm control valve stem ends-oriented structure, using the middle of the long-pitch-oriented guide to avoid the hole on the valve cover and seat due process or install a different heart, cause stem movement blocked, easy stuck phenomenon. The middle of the guide sleeve and the body as a whole casting, machining accuracy is guaranteed, while the contact surface between the stem plus a bronze bushings, protecting the stem surface is not being worn, rub the hair, so that the valve stem moves freely, smoothly, flexible.

Remove the whole assembly and easy maintenance

The second generation of hydraulic control valve diaphragm valve cover, the upper chamber, the valve stem, the valve plate can be taken as a whole, easy maintenance and replacement of rubber sealing surfaces, O-rings and other wearing parts. Diaphragm valve cover and the upper chamber between the use of nylon mesh reinforced rubber diaphragm, resistance to shear stress, the use of safe and reliable.

The second generation of hydraulic diaphragm control valve trim, including the upper chamber, the valve stem, the valve disc, playing praise, bolts, etc., in addition to stainless steel parts are made non-toxic spray, has a good anti-rust function.

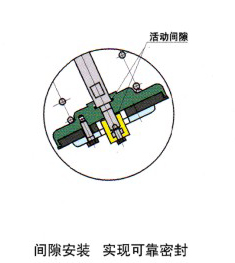

Install reliable sealing gap

The second generation of hydraulic control valve diaphragm valve disk space using a combination of structure, that bore the main stem and the valve disc has a certain gap between; disc with screws and stopper relatively fixed between the stem and leaves 1-2 mm gap, so that the valve disc in a plane perpendicular to the stem of a high degree of freedom, can make up caused by dry processing or assembly error seat sealing surface and the valve stem is not perpendicular to the defect, to achieve one percent of zero leakage.